News

What are the materials commonly used for making molds?

Commonly used Bai materials for mold: T7, T8, T12, 6CrW2Si, 5CrMnMo, Cr12, Cr12MoV. The die material is different when the die is used in different ways.

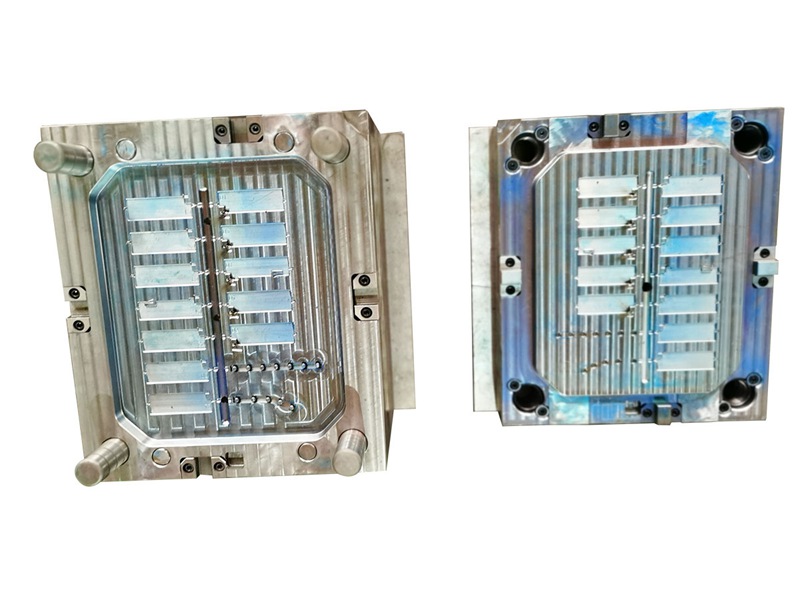

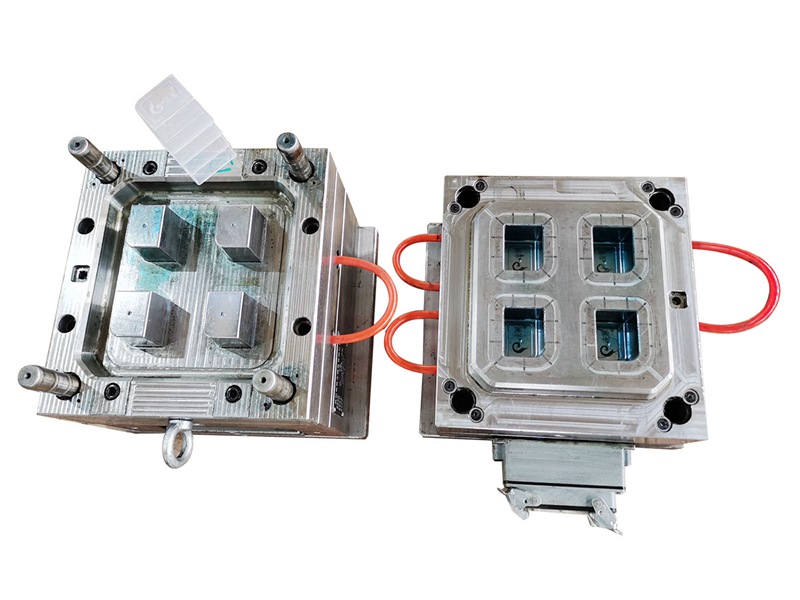

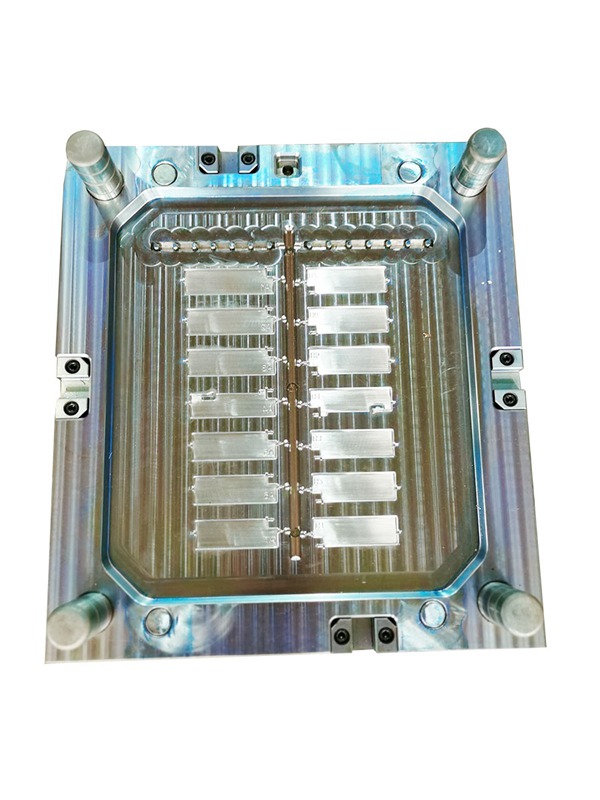

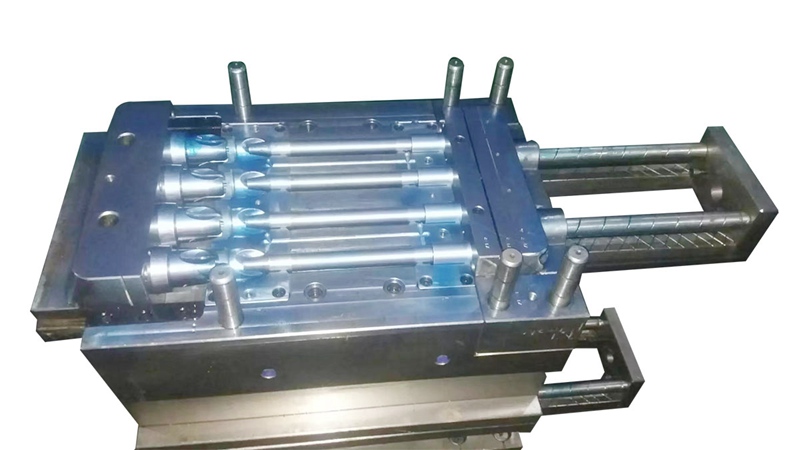

1. Die is a tool to make the blank into a part with specific shape and size under the action of external force Dao. It is widely used in blanking, die forging, cold heading, extrusion, powder metallurgy parts pressing, pressure casting, as well as molding or injection molding of engineering plastics, rubber, ceramics and other products. The die has a specific contour or cavity shape, and the blank can be separated (blanking) according to the contour shape by using the contour shape with edge. By using the shape of the inner cavity, the blank can obtain the corresponding three-dimensional shape.

2. The die generally includes two parts: moving die and fixed die (or punch and die), which can be separated and closed. The parts are taken out when they are separated, and the blank is injected into the die cavity for forming when they are closed. Die is a precision tool with complex shape and bears the expansion force of blank. It has high requirements for structural strength, stiffness, surface hardness, surface roughness and machining accuracy. The development level of die production is one of the important signs of mechanical manufacturing level.

This article is reprinted from "Baidu knows"

欄目導(dǎo)航

聯(lián)系我們

郵箱:598596665@qq.com

電話:0576-89184833

手機(jī):13757670503

公司地址:浙江省臺州市黃巖區(qū)新前街道厚施路28號

客服2

客服2